NDT Services

Welcome to QUINSPEK TECHNICAL, your trusted provider of comprehensive non-destructive testing (NDT) solutions. Our expertise includes Magnetic Testing (MT), Penetrant Testing (PT), Visual Testing (VT), and Ultrasonic Testing (UT), ensuring the integrity and reliability of your assets. Our certified professionals uphold the highest standards of quality and safety across industries like manufacturing, construction, and maintenance.

Advanced NDT Services

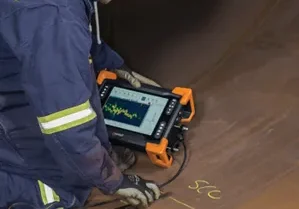

PAUT – Phased Array Ultrasonic Inspection

Phased Array Ultrasonic Testing (PAUT) uses an array of ultrasonic elements to generate customise waveforms, enhancing flaw detection and inspection accuracy. Applications include tank welds, bolt inspection, and turbine components. Advantages include flexibility for unique geometries, in-situ inspections, and accurate sub-surface defect detection.

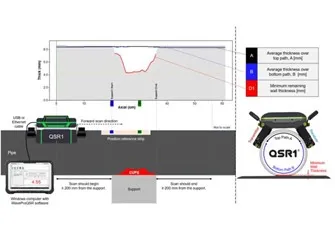

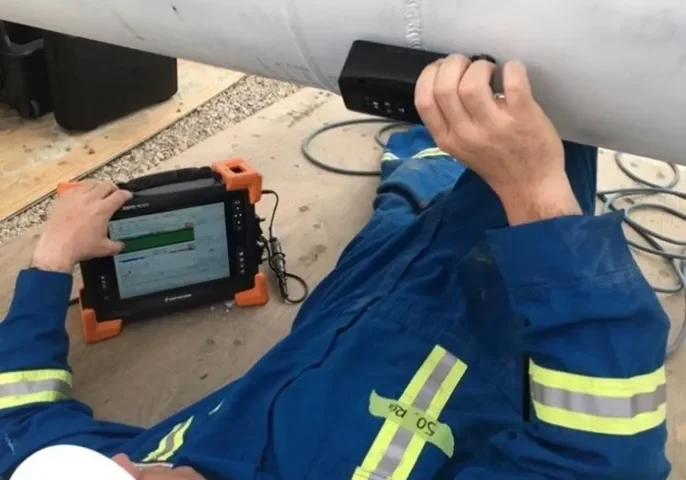

LRUT/GWT – Long Range Ultrasonic Testing/Guided Wave Testing

Long Range Ultrasonic Testing (LRUT) inspects extensive lengths of pipework for defects, welds, and supports. Applications include corrosion under insulation (CUI), buried piping, and structural columns. Advantages include long-distance inspection from a single point, minimal downtime, and rapid results.

ET – Eddy Current Testing

Eddy Current Testing detects surface and sub-surface defects in conductive materials without removing surface coatings. Advantages include immediate results, portability, and safety. Applications include painted structures, cranes, and road tankers.

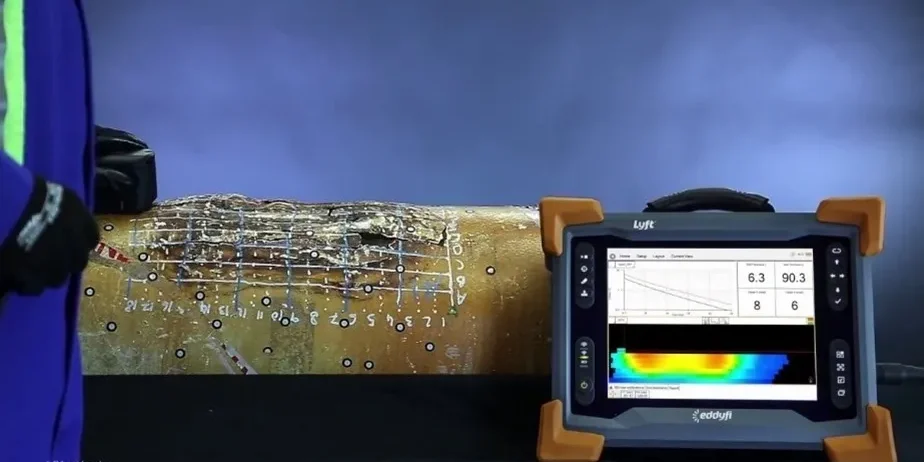

ECA – Eddy Current Array

Eddy Current Array (ECA) utilises multiple coils for enhanced defect detection and high-resolution inspections. Advantages include improved coverage, real-time data processing, and adaptability to various materials and shapes. Limitations include surface preparation requirements and limited penetration depth.

PECT – Pulsed Eddy Current Testing

Pulsed Eddy Current Testing assesses conductive materials through non-conductive coatings. Advantages include deep penetration, efficient inspection, and suitability for complex geometries. Limitations include measurement variability near edges and % average thickness measurement at test locations.

Trust QUINSPEK TECHNICAL for precise, dependable NDT services tailored to your needs.