Asset Integrity Services

NACE Coating Inspection and Assessment

Surface coatings are vital for preventing component degradation and financial losses due to corrosion. Our NACE-certified coating inspectors use advanced techniques to ensure coatings meet high standards, enhancing durability and protecting assets across industries.

- Coating selection for specific applications

- Epoxy Mix Ratio Testing

- Dry Film Coating Thickness Testing

- Holiday Coating Continuity Testing

- Coating Adhesion and Peel Testing

- Surface Roughness Testing

- Coating materials analysis using SEM and FTIR analysis

- Coating Failure Analysis

Pipeline Inspection

Pipeline inspections are essential for maintaining integrity and safety. Our inspectors and engineers utilise advanced non-destructive testing (NDT) methods to detect internal and external issues and manufacturing flaws.

- Inspection and Assessment: Compliant with AS/NZS 3788 and ASME B31G standards

- Pressure-test Verification

- Pipeline Integrity Management Plans (PIMPs)

- Hydrostatic Testing

Pressure Equipment Inspection

Pressure equipment, including vessels, boilers, and high-energy piping, requires thorough inspection to ensure safety. Our services are tailored to client needs, adhering to Australian and international standards.

- Fabrication and In-Service Inspection

- Non-Destructive Testing (NDT)

- Risk-Based Inspection (RBI) per API 580 and API 581

- Compliance and Assessment: Design and Item Registration, hazard assessments

- Fitness For Service (FFS) Assessment per API 579, BS7910, B31G

- Advanced Techniques: Laser scanning, pipe stress analysis, finite element analysis

- Welding and Repair Supervision

- Metallurgical Analysis

- Coatings and Corrosion Protection Consultancy

- Non-Intrusive Inspection (NII)

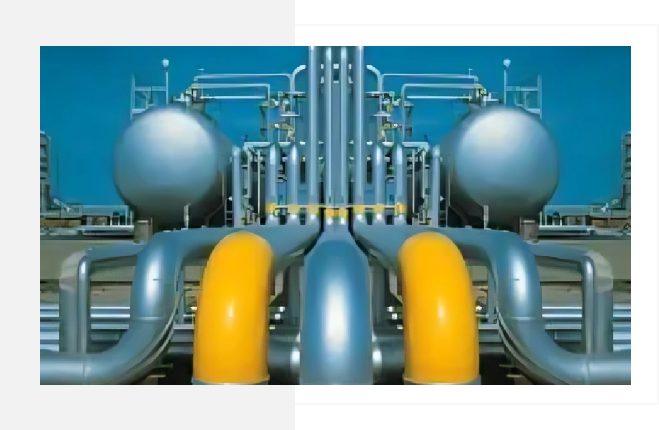

Remote Inspection

We leverage drone and borescope technologies to deliver accurate, efficient, and safe inspection services.

- Access to difficult areas

- High-resolution imaging

- Real-time data collection

- Enhanced safety and efficiency

- Internal visualisation

- Compact and flexible design

- Non-destructive inspection

- Detailed internal assessments

Crawler Inspection

Our crawler technology provides thorough evaluations of hard-to-reach or confined spaces.

- Enhanced accessibility to rugged and confined environments

- High-resolution imaging

- Real-time data collection

- Versatile applications: Tank, pipeline, and infrastructure inspections

Tank Inspection

Proper tank management is crucial to prevent catastrophic failures and ensure compliance. Our API-certified inspectors use advanced techniques to deliver optimised inspection and management programs.

- Extended Inspection Intervals

- Design and Implementation of Inspection Plans

- Minimisation of Tank Downtime

- Risk Understanding and Management

- Compliance with Regulatory Requirements

- Cost Optimisation

Additionally, We Provide

Trust QUINSPEK TECHNICAL for comprehensive inspection services that prioritise safety, compliance, and operational efficiency.